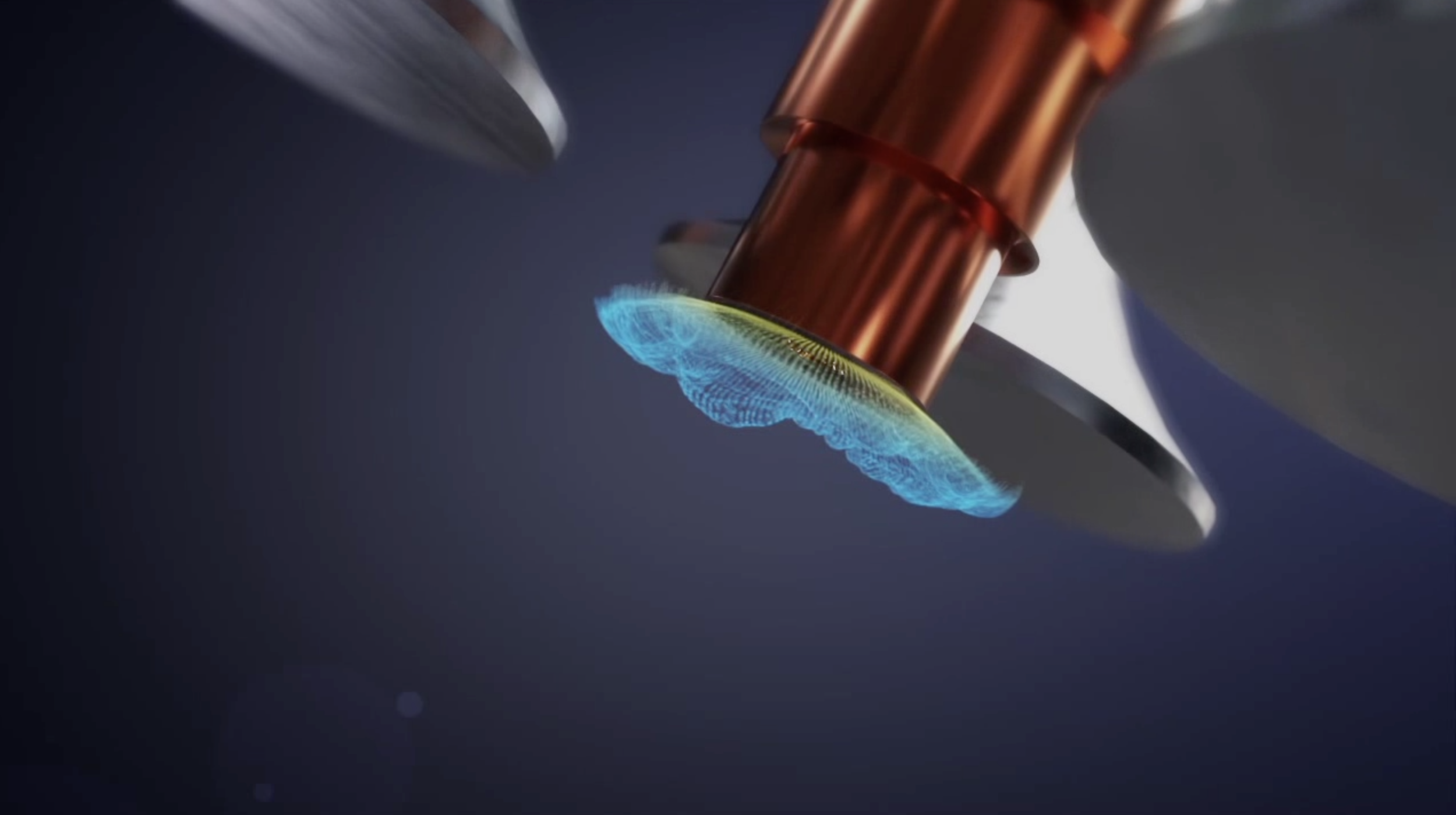

blue flame technology for a greener world.

a self-pressurising injector to dramatically reduce engine emissions.

The RK Injector (RKI) is a unique breakthrough in fuel injection technology. It is a self-pressurising injector that interacts with the pressure in the combustion chamber, allowing fuel to be injected at a much higher pressure (5000+ bar), so combustion takes place at a much lower temperature. These optimal mixing conditions facilitate a much cleaner burn, eliminating the formation of NOx. This can create more than 15% improved fuel efficiency, with less emissions. Our key market focus is on heavy duty marine, rail and trucks, plus electricity generating sets, mining, construction and agricultural machinery.

We call this our Blue Flame technology - an engineering innovation that contributes to a greener world.